VISTA BATCH

Automate Batch Treatments with Dynamic Scheduling

Vista Chemical Batch Controller

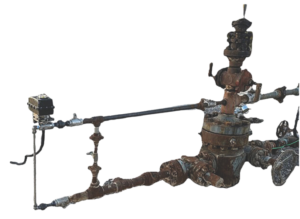

By automating batch treatment calculations in real time, DCiii’s Vista Batch controller becomes your virtual chemical optimization technician. As your process or production variables change so can your batch amounts. From rod pumped wells to pipeline’s, Vista Batch delivers the optimized chemical dosage for each treatment. Remove the guess work in your batch programs by implementing an automation solution that works for you every day.

Benefits

» Automated Batch Treatments: On-site equipment performs chemical batch treatments without pump trucks by retrofitting standard chemical injection equipment used in continuous applications.

» Pump Variance and Drift Elimination: Eliminate and compensate for pump drift, even with solar-powered systems (up to 40% daily), ensuring optimal chemical delivery.

» Rate Adjustment Based on Production Variables: Automatically adjusts the batch volume and/or frequency of treatments in response to changes in production.

» Verified Chemical Injection: Verification of batch treatments and volumes used.

» Direct Pump Monitoring: A proactive approach to verify injection delivery, enhancing the reliability and effectiveness of your chemical treatment.

» Lower LOE: Reduce failures and leaks by dynamically adjusting your batch program to eliminate under treatment.

Features

» Versatile Pump and Tank Usage: Use any pump or tank, offering flexibility in diverse field conditions.

» Advanced Tank Level Monitoring: Keep a constant eye on tank levels, ensuring uninterrupted operations.

» Flush Sequence Control Valve: Optional flush control valve can operate in sync with batch treatments to mimic treater truck operations with pre-flush, sync-flush and post flush set points.

» Eliminate Contaminated Fluids: Using fluid from the well for diluent and carrier fluid(flush), you can minimize or eliminate the introduction of bacteria and incompatible fluids from treater tuck operations.

» Flowrate-Based Injection Adjustment: Dynamically adjust batch volumes and treatment intervals based on real-time flowrate changes.

» Remote Control Capability: Manage and control and change your batch schedule remotely or locally when.

» Manual Batch Mode: Ad-hoc batch treatments can be triggered as needed.

» Battery Health Monitoring: Monitor and assess battery health (volts/amps), preempting power-related issues.

» SCADA Integration: Easily integrate into existing SCADA systems for streamlined operations.

» Pump Calibration Fingerprint: Monitor when technicians calibrate chemical pumps to maintain precise chemical injection, maintaining consistent treatment efficacy.

» DC3 Portal Option: Access to a specialized portal for enhanced data analysis and control.

Technical Specifications

» Dimensions & Weight: [Include specific dimensions and weight from the technical datasheet]

» Compatibility: Designed to work seamlessly with a variety of chemicals, pumps, and tanks.

» Power Requirements: 10-32 VDC, 110/120 VAC

» Connectivity: RS485, TCP-IP, Integrated SignalFire 900MHz radio. DC3 cloud portal optional.

» Material & Build: Constructed with 304SS, 316SS Teflon wetted parts, additional material available.

» Environmental Tolerance: Designed to operate efficiently in any climate, making it suitable for diverse field applications.

How It Works

The Vista batch controller with optional flush control system operates in 3 modes. You simply enter the setpoints per the design of your batch treatment to start treatments.

Batch Volume Control – Volume and interval of batch treatments are fixed and will repeat until changed.

AutoTrack Time Batch Control – By tracking your production over time, the volume of chemical injected during the batch will change to achieve the correct target dosage amount with a fixed interval time.

AutoTrack Volume Batch Control – By tracking your production over time, the frequency of your batch will automatically adjust with your fixed dosage amount.

Batch On Demand – Non repeating batches that can be triggered on demand at the volume required for an ad-hoc batch treatment.

Optional Flush Sequencing Control Valve – Set points for Pre-Flush, Sync-Flush and Post-Flush creates a customizable batch that mimics treater truck operations.