Vista

Streamlined Automation for Marginal Injection Points.

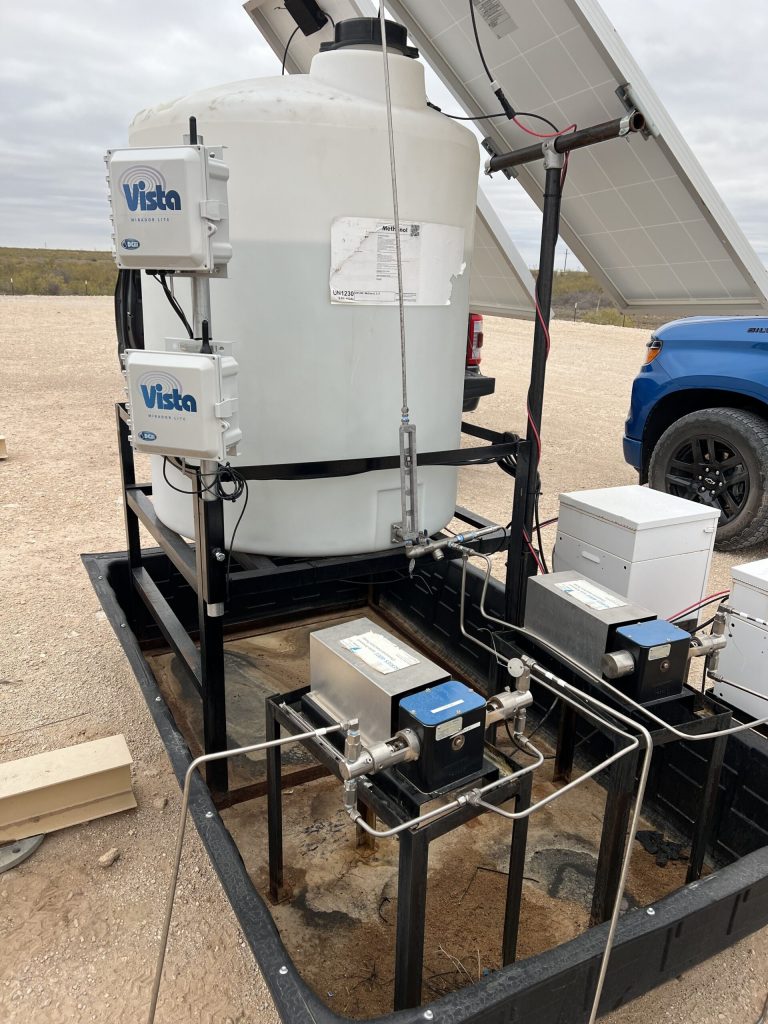

The Vista is the most economical solution to control and monitor your marginal injection points

Building on the success of our flagship Mirador system, DC3 proudly presents Vista. Tailored for marginal injection points, Vista offers a cost-effective, labor-saving solution for operators and CSPs. With its reduced size and functionality, yet retaining the core features of the Mirador, The Vista is perfect for less critical applications where smart, straightforward automation is key.

How its Works

Vista harnesses the power of thousands of Miradors in the field, utilizing this vast dataset to algorithmically control pumps and report rates. Perfect for less critical applications, it offers a balanced mix of features and ease of use. The Vista adjusts injection rates based on real-time production data, ensuring optimal chemical utilization. Its user-friendly interface and remote-control capabilities make it an ideal choice for operators seeking efficient, reliable automation in their chemical injection programs.

BENEFITS:

FEATURES:

TECHNICAL SPECIFICATIONS: